[Kejie Technology, Ultimate Cutting] CNC machining center JTVC-855P3 Shocking release!

At present, the power of high-tech production in China is constantly developing. In order to further promote the high-quality development of domestic high-end production, Kejie Technology has launched a new upgraded JTVC-855P3 CNC machining center for batch processing products.

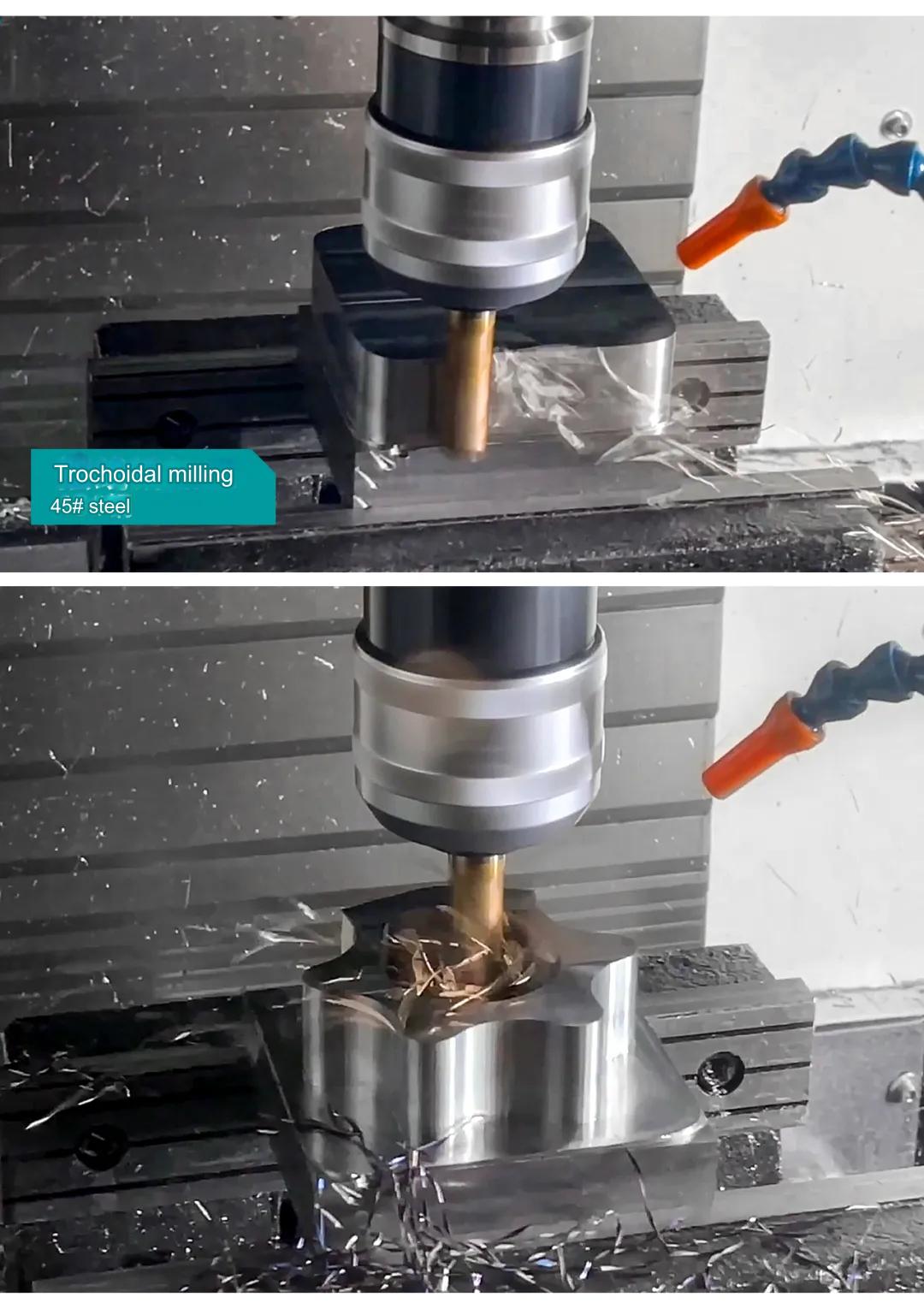

The mechanical structure of the linear guide ensures machine sensitivity and stability, allowing the machine to maintain accurate movement during long processing. Unique and advanced structural design and dynamic characteristics make it easy to achieve high-speed processing of several types and processes, such as milling, drilling, boring and milling, threading, drilling, etc. D. With great removal.

Solve the disadvantages of industrial processing, such as short tool life, poor finish and unstable accuracy, and bring customers an excellent processing experience and feel the joy of efficient cutting processing.

The machine is suitable for processing complex parts, such as small and medium-sized boxes, covers, routes, plates, housings, valves, cams, fixtures, equipment, etc. D. In aerospace, auto parts and medical, electronic and electrical, communication production and other industries.

PART/1

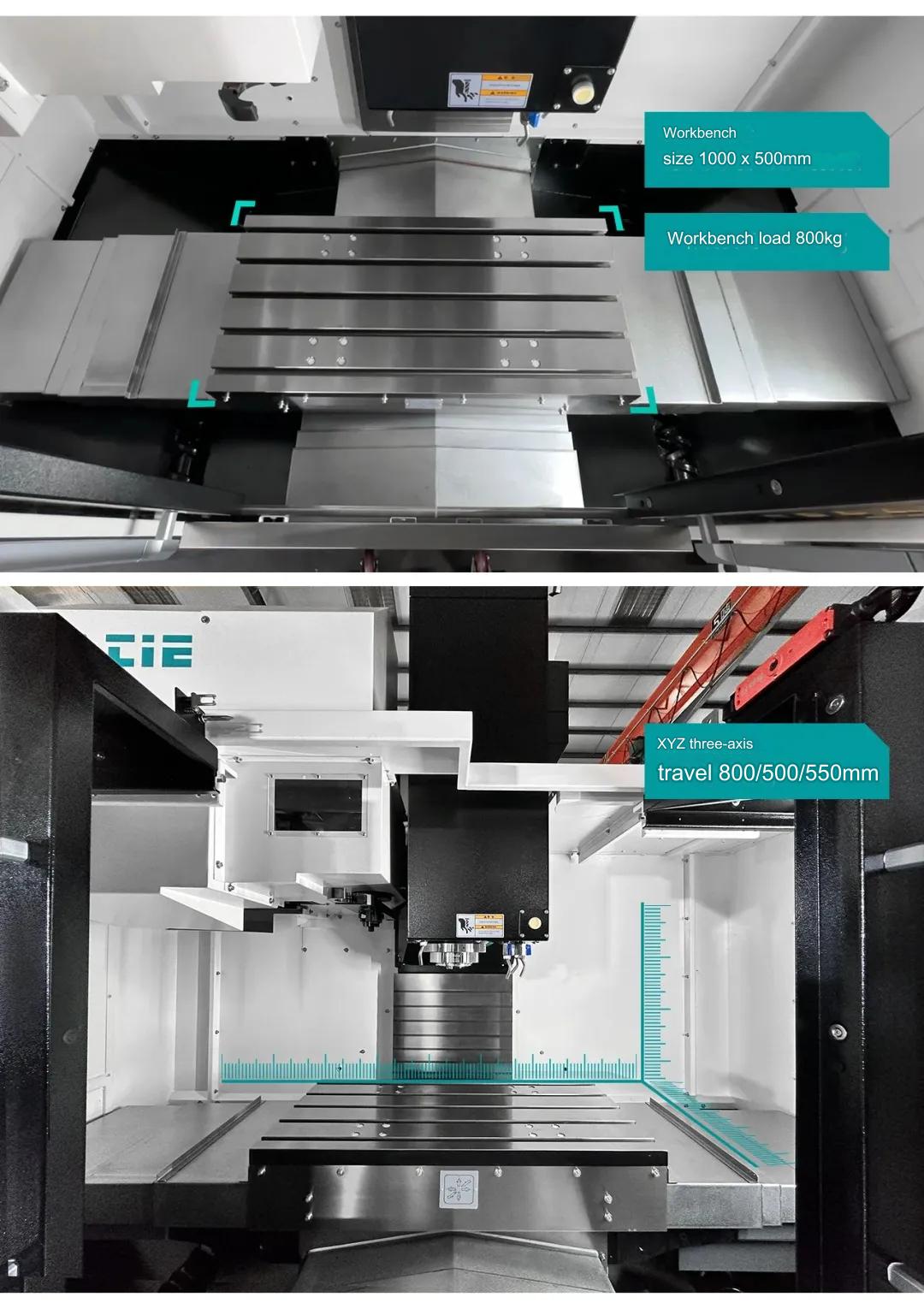

More processing space can satisfy the processing of larger workpieces.

PART/2

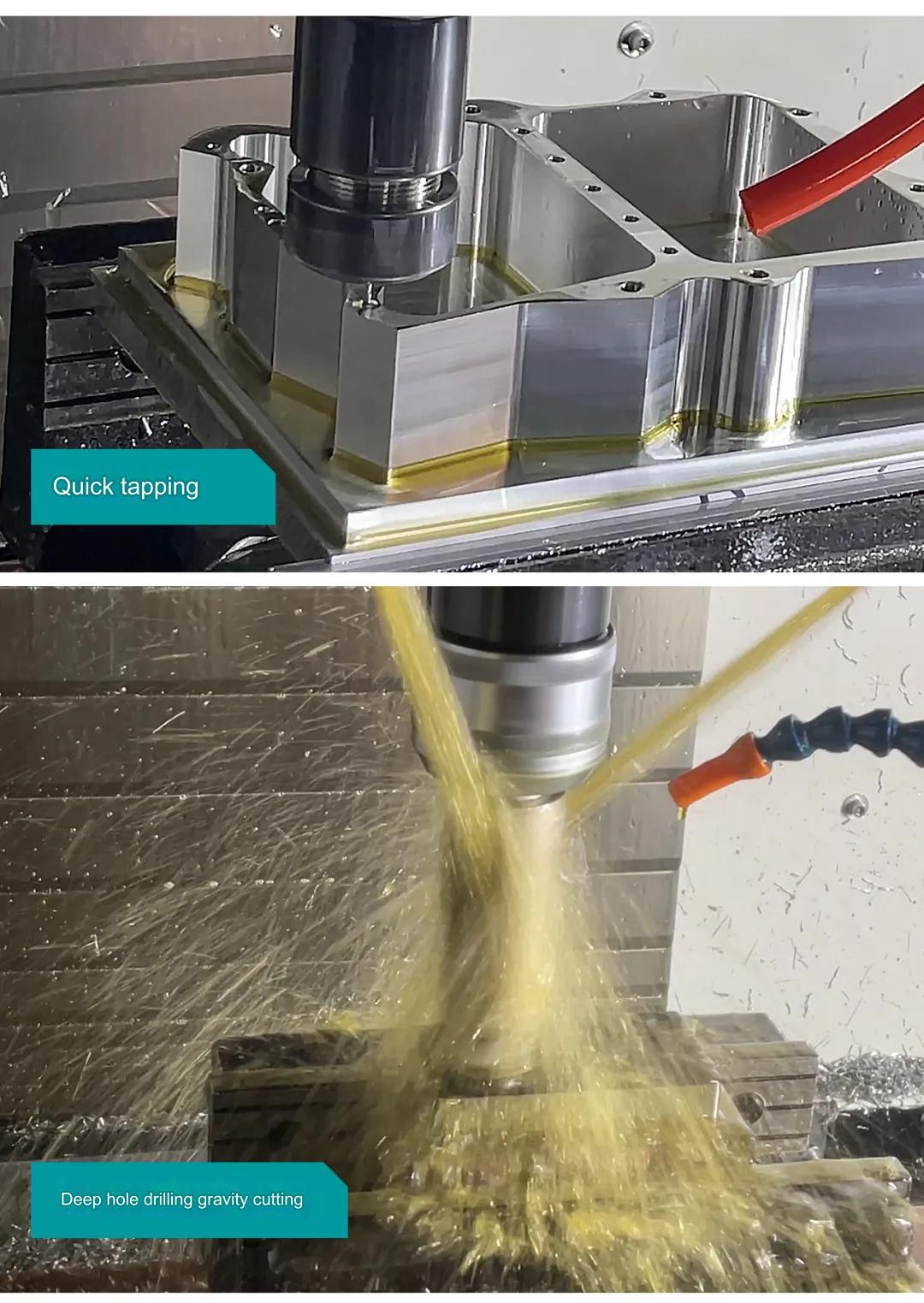

Using high efficiency BT40 or BBT40 tool interface, 12000 rpm spindle, with powerful motor, cutting performance higher.

PART/3

It can perform high-speed cutting, drilling, threading and other high-speed processing of aluminum and aluminum alloy materials with high processing efficiency.

PART/4

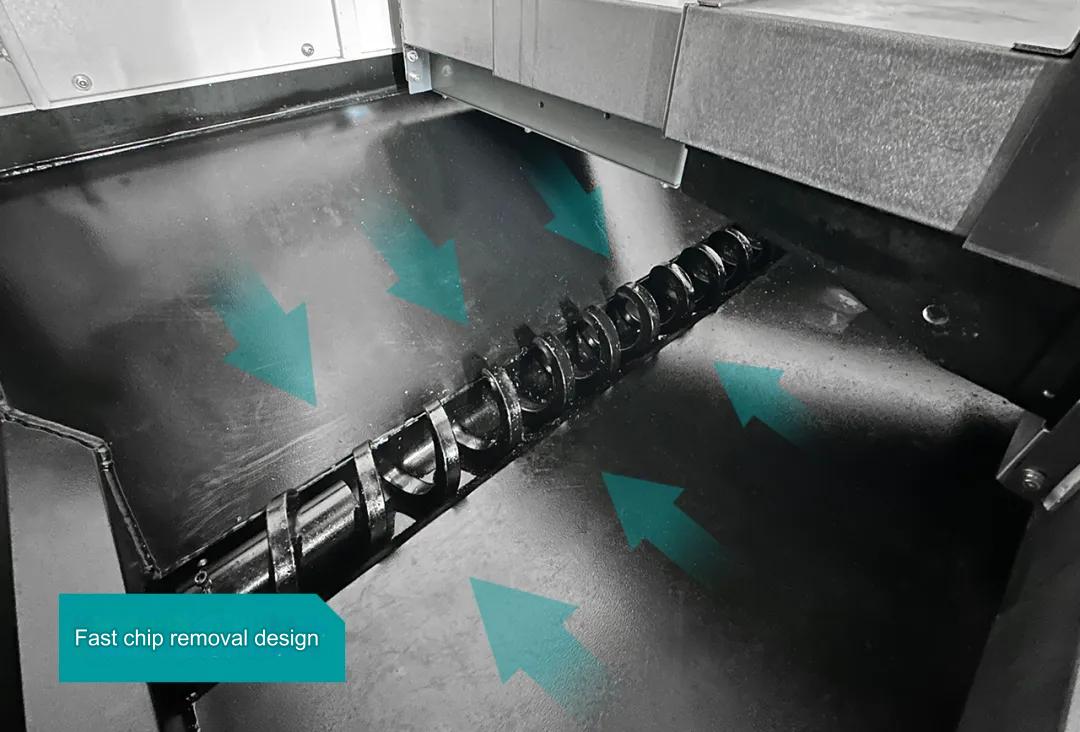

The chip remover is equipped with two side slopes and a rear water tank structure, which is convenient and efficient.

PART/5

Optional system FANUC 0I-MF Plus (standard 5 packs) or JATIE JT810.

Product Highlights

1. Unique design effectively guarantees the overall dynamic characteristics of the machine.

2. The three axes are designed with linear rails, low friction and low noise, which ensures machine sensitivity and stability and precision machining during rapid movement.

3. High speed direct drive spindle is adopted, and the rated power of the spindle motor can reach 11 kW, and the rated torque is 52 N · m.

4. high-precision machining, positioning accuracy can reach 8 μm, and re-positioning accuracy can reach 5 μm.

5. Tool tool type tool shop has 24 pieces capacity, high speed tool change, stable and excellent.

6. Used the BT40 high-control tool interface, combines powerful motor, and cutting performance is better.

7. The chip remover is standard double-sided near the slope, and the water tank is installed at the back, which is humane and efficient.

8. Good human-machine interaction design, the whole machine is fully closed for protection and easy to operate.

| Project | Name | Parameter |

| CNC system | High Speed CNC System | FANUC 0I-MF Plus (5 packs as standard) or JATIE JT810 |

| Engine power | 7.5/11 kW | |

| Spindle | Maximum speed | 12000 rpm |

| Applicable tool holder | BT40/BBT40 | |

| Moving parts | Ball-helical transmission, roller linear guide | Accuracy rank |

| Feed speed | Fast movement speed | 48 m/min |

| Maximum cutting speed | 30 m/min | |

| Travel | Xxyxz | 800x500x550 |

| Machine Size | Length x Width x Height | 2480x2700x2720 |

| Machine weight | Main body | 4500 kg |

| Fully automatic tool installation | ||

| 4th axis | ||

| Additional Parts | Oil Mist Manifold | |

| Stable supply voltage | ||

| Automatic chip conveyor | ||

JTVC-855P3 CNC machining center helps upgrade and improve product processing efficiency and usher in the era of efficient processing!